BETTER TOUCH BETTER BUSINESS

Contact Sales at KAIDI.

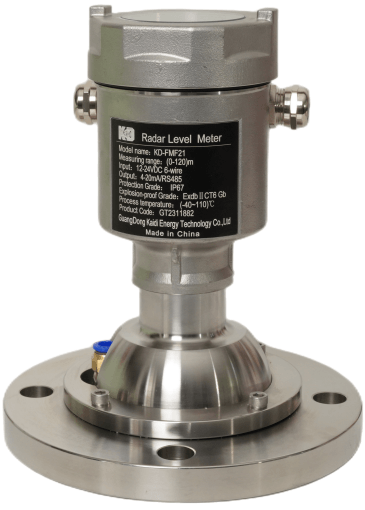

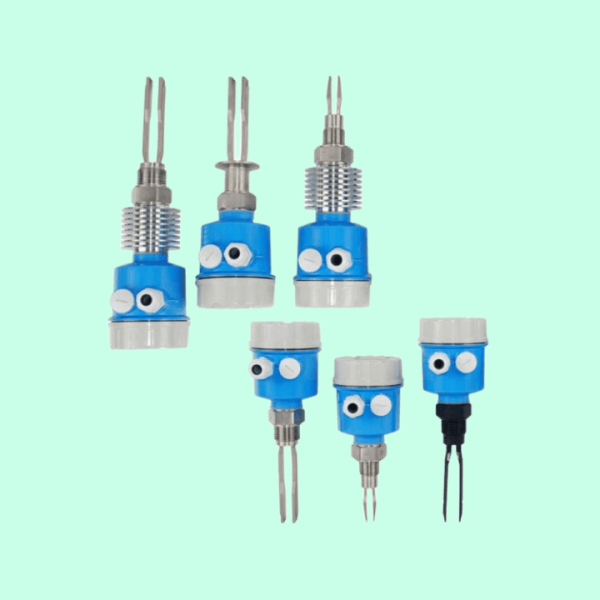

As we all know, the formation of an explosion needs to meet three conditions, namely for oxygen, explosive gases, detonation source. Explosion-proof measures must be taken in the electrical engineering, installation and construction, operation and maintenance and safety and technical management of explosion-hazardous places to achieve overall explosion-proof. The use of explosion-proof instrumentation without safety hazards can play a real protective role. For this reason, Guangdong Kaidi Energy Technology Co., Ltd.'s vibrating bar level switch, tuning fork level switch, tuning fork liquid level switch, radar level meter and other instruments have passed the national explosion-proof certification. So, what are the types of explosion proof pressure transducer, and what are the precautions in the installation and maintenance process?

I. Types of explosion-proof instruments and their safety grids

1、Kinds of explosion-proof instruments

(1) explosion-proof instrumentation

Is the instrument shell can withstand the pressure of the internal explosion, the internal explosion can not cause an external explosion of the instrument, the symbol is d.

(2) intrinsically safe instrumentation

It is the instrument whose circuit system can not ignite the specified explosive mixture under normal operation or fault state of electric spark and thermal effect, marked as ia.

2、The types of safety grille

Safety grid is generally installed in the control room, as the control room instrumentation and field instrumentation associated equipment, on the one hand, to transmit signals, on the other hand, to control the flow of energy into the dangerous place in the explosive gas or mixture of ignition energy below, to ensure the safety of the system spark performance.

There are mainly the following types of safety barriers:

1)Resistance type safety grille: It uses the current limiting effect of resistance to limit the energy flowing into the place to below the critical value, so as to achieve the purpose of explosion-proof.

2) Zener Safety Barrier: It is based on the reverse breakdown performance of Zener diode and works.

3) Relay Amplified Safety Barrier: Developed from resistive safety barriers, the high input impedance of the amplifier is used to increase the impedance of the current limiting resistor connected in series in the input circuit to achieve safe spark explosion protection.

(4) Isolation type safety barrier: is to ensure the safety spark performance by isolation, voltage and current limiting measures to limit the flow of energy into the dangerous place. The main measures are: insulation, energy limiting.

Second, the installation of explosion-proof instrumentation precautions

Instruments and installation materials installed in explosive hazardous places should have nameplates and explosion-proof signs, and their models and specifications should be checked before installation to see if they meet the design requirements, and their exteriors should be free of damage and cracks.

Explosion-hazardous places within 1 meter wiring, cable, wire must be laid with galvanized steel pipe through the pipe. Wiring between the protection tube, protection tube and junction box, cable box, should be used between the cylindrical pipe thread connection.

Protection tube, sink, cable trench through the different levels of explosive hazard area boundary, should take sealing measures (such as explosion-proof flame arrestor, sealing components isolation, filling seal, etc.) to prevent explosive gases from a dangerous place into another dangerous place string.

Protection tube and field instrumentation, detection components, electrical equipment, instrumentation boxes, junction boxes and pull boxes connected, should be installed within 0.45m of the connection explosion-proof sealing pipe fittings, if necessary, do filling seal. Seal fittings and field instruments, detection components, electrical equipment can be used between the flexible pipe connection.

Three, the use of explosion-proof instrument matters of note

1、Check whether the instrument shell has Ex mark, and whether the explosion-proof mark is consistent with the regulations of hazardous substances on site.

2, intrinsically safe transmitter must be equipped with a safety grid, in order to use in dangerous situations.

3, the instrument housing must have a good grounding.

4, in dangerous occasions, the power must be disconnected before opening the cover.

5, the intrinsically safe transmitter incoming cable specifications by the joint forensic safety grille regulations.

Four, explosion-proof instrument maintenance precautions

Explosion-proof instrumentation should always be inspected and maintained, and the inspection should look at the appearance of the instrument, the environment (temperature, humidity, dust, corrosion), vibration, and whether the installation is solid.

In the case of power on the explosion proof pressure sensor instrument maintenance, do not open the junction box and observation window, need to open the cover maintenance must first cut off the power supply, never allow the cover maintenance with electricity.

Maintenance shall not produce sparks, the test instrument used should be flameproof or intrinsically safe instrumentation to avoid test instrumentation caused by induced sparks or excessive voltage to inappropriate parts.

Disassembly should be careful to protect the flameproof thread and flameproof plane, shall not be damaged and scratched, especially the flameproof plane does not allow longitudinal scratches.

When disassembling the rubber sealing components, do not use sharp instruments hard pry, hard smash, and shall not have any longitudinal scratches on its sealing surface.

When assembling, should be in the order of assembly, anti-loosening parts, fasteners shall not be missed.

Corrosion and damaged components should be replaced in a timely manner, aging, damage and can not seal the role of rubber sealing components should also be replaced in a timely manner.

After regular maintenance of the instrument, it should be confirmed that the explosion-proof performance has been restored before it is put back into use.

The above is the "explosion-proof instrumentation and its installation and maintenance of those considerations" related to the introduction, if you want to know more level switch (level switch, level switch), level meter (level meter, level meter) and other level measurement instrumentation knowledge, welcome to pay attention to and consult us!

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist