Related Products

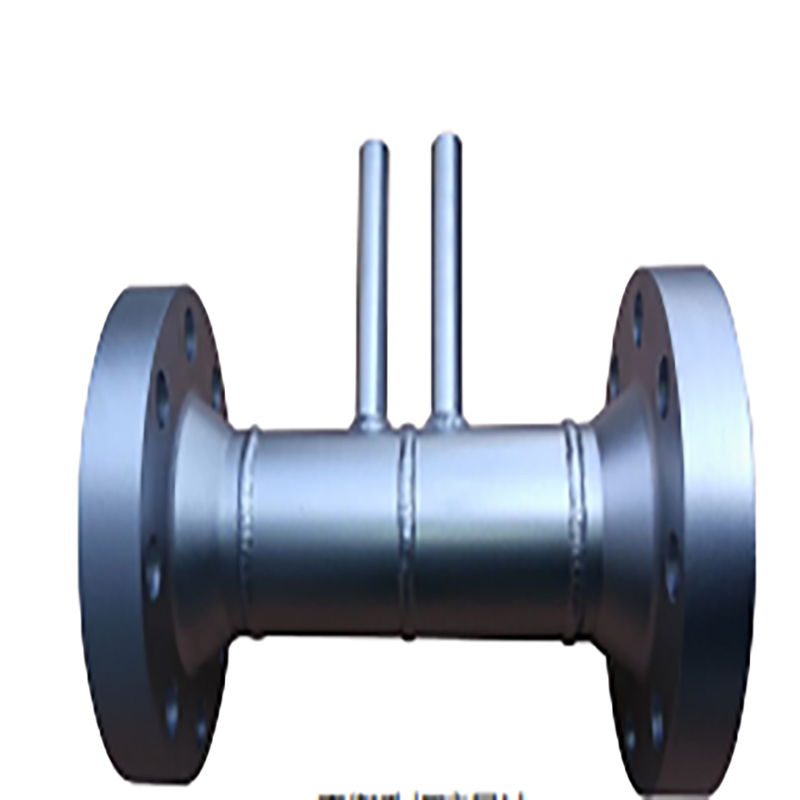

| Application: | Liquid, gas, steam, mixed phase flow |

|---|---|

| Measuring Range: | 15 mm ≤ DN ≤ 1200mm |

| Accuracy: | 0.5 grade, 1.0 grade |

| Process Pressure: | -50℃≤ t ≤ 550℃ |

| Process Temperature: | -50℃≤ t ≤ 550℃ |

| Outer Covering: | Can be selected according to the measurement medium |

| MOQ | 1 SET |

| Payments: | TT, Paypal, Credit card, Western union |

| Shipping ways: | Express(DHL,Fedex,TNT,EMS,UPS)/Air/Sea |

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist